Consider the brass alloy for which the stress strain behavior, an intricate relationship that unveils the mechanical characteristics of this versatile material. This discourse delves into the factors that shape this behavior, exploring the influence of composition, microstructure, and temperature.

Prepare to embark on a journey that unravels the secrets of brass alloys, their mechanical properties, and their diverse applications.

Brass alloys, renowned for their exceptional mechanical properties, find widespread use in musical instruments, jewelry, and marine hardware. Their strength, ductility, and corrosion resistance make them ideal for these demanding applications. Understanding the stress strain behavior of brass alloys is paramount in harnessing their full potential.

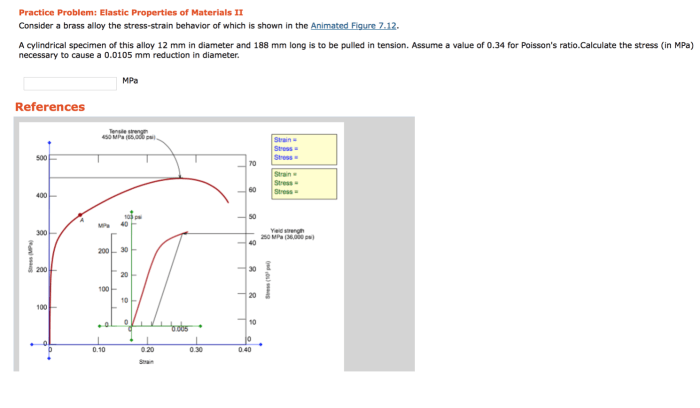

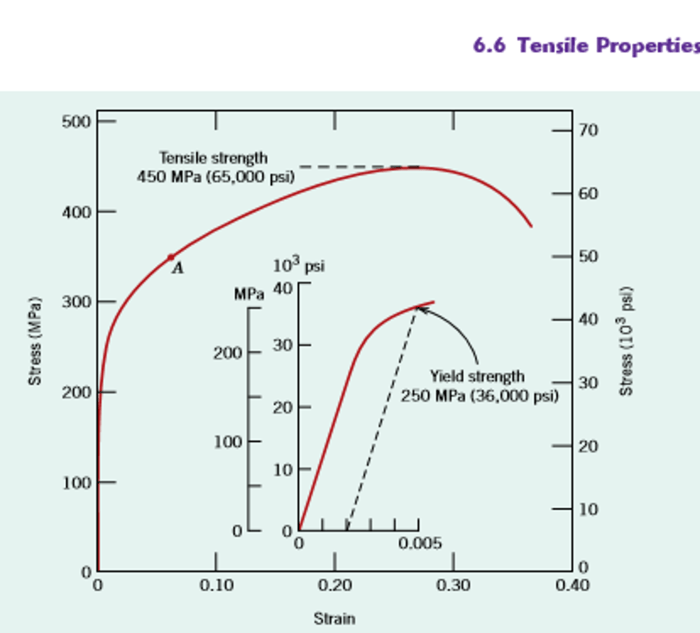

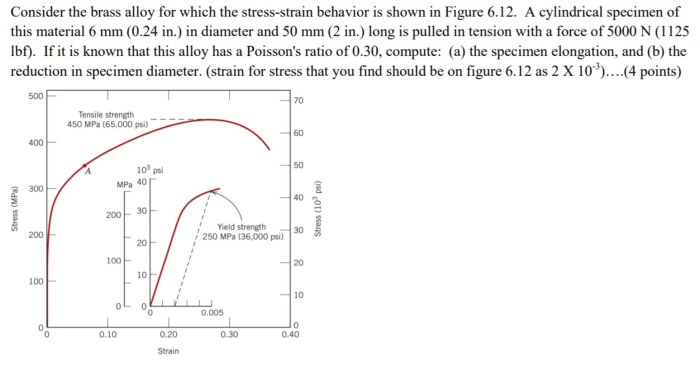

Stress-Strain Behavior of Brass Alloy

Brass alloys exhibit a characteristic stress-strain behavior that is influenced by their composition, microstructure, and temperature. The stress-strain curve for a brass alloy typically shows a linear elastic region followed by a plastic region with work hardening. The yield strength, which represents the onset of plastic deformation, is a key parameter in determining the strength of the alloy.

The stress-strain behavior of brass alloys is affected by the following factors:

- Composition:The composition of the brass alloy, particularly the proportion of copper and zinc, influences its strength and ductility. Higher zinc content generally results in higher strength and lower ductility.

- Microstructure:The microstructure of the brass alloy, including the grain size and distribution of phases, affects its mechanical properties. A finer grain size and a more homogeneous microstructure typically lead to higher strength and ductility.

- Temperature:The temperature at which the brass alloy is tested or used can also affect its stress-strain behavior. Higher temperatures generally result in lower strength and higher ductility.

Mechanical Properties of Brass Alloy

Brass alloys possess a range of mechanical properties that make them suitable for various engineering applications. The following table summarizes the typical mechanical properties of brass alloys:

| Property | Value |

|---|---|

| Tensile strength | 350-650 MPa |

| Yield strength | 200-450 MPa |

| Elongation | 20-50% |

| Hardness | HB 100-250 |

Compared to other common engineering materials, brass alloys generally have moderate strength and ductility, good corrosion resistance, and good machinability.

Applications of Brass Alloy

Brass alloys are widely used in a variety of applications due to their unique combination of properties. Some of the common applications of brass alloys include:

- Musical instruments:Brass alloys are used in the construction of musical instruments, such as trumpets, trombones, and saxophones, due to their excellent acoustic properties and corrosion resistance.

- Jewelry:Brass alloys are used in the production of jewelry, such as bracelets, necklaces, and earrings, due to their attractive appearance, durability, and affordability.

- Marine hardware:Brass alloys are used in marine hardware, such as propellers, fittings, and valves, due to their corrosion resistance and ability to withstand saltwater environments.

- Industrial applications:Brass alloys are used in a variety of industrial applications, such as heat exchangers, condensers, and electrical components, due to their good thermal conductivity and electrical properties.

Design Considerations for Brass Alloy

When using brass alloys in engineering applications, several key design considerations must be taken into account:

- Corrosion resistance:Brass alloys are generally corrosion resistant, but the specific composition and environment can affect their corrosion resistance. Proper selection of the alloy and protective coatings can be necessary to ensure long-term performance in corrosive environments.

- Wear resistance:Brass alloys have moderate wear resistance, but the addition of alloying elements or surface treatments can improve their wear resistance for specific applications.

- Machinability:Brass alloys are generally easy to machine, which makes them suitable for complex shapes and high-volume production.

By carefully considering these design considerations, engineers can select the appropriate brass alloy and design for optimal performance in their applications.

Future Trends in Brass Alloy Development

Research and development efforts are ongoing to improve the properties and expand the applications of brass alloys. Some of the current trends in brass alloy development include:

- Development of high-strength brass alloys:Researchers are exploring new alloy compositions and processing techniques to develop brass alloys with higher strength while maintaining good ductility and corrosion resistance.

- Exploration of new applications in advanced manufacturing:Brass alloys are being investigated for use in advanced manufacturing processes, such as additive manufacturing and microfabrication, due to their unique properties and potential for customization.

- Development of environmentally friendly brass alloys:Researchers are also working on developing brass alloys with reduced environmental impact, such as by using recycled materials or exploring alternative alloying elements.

These trends suggest that brass alloys will continue to play an important role in various engineering applications in the future.

FAQs: Consider The Brass Alloy For Which The Stress Strain Behavior

What is the significance of stress strain behavior in brass alloys?

The stress strain behavior of brass alloys provides crucial information about their mechanical properties, such as strength, ductility, and toughness. Understanding this behavior enables engineers to design components that can withstand specific loads and deformations.

How does composition affect the stress strain behavior of brass alloys?

The composition of brass alloys, particularly the proportions of copper and zinc, significantly influences their stress strain behavior. Different compositions result in variations in strength, ductility, and other mechanical properties.

What role does microstructure play in the stress strain behavior of brass alloys?

The microstructure of brass alloys, including grain size, shape, and distribution, affects their stress strain behavior. Microstructural features influence the strength, ductility, and toughness of the material.