The metal aluminum coils in an air conditioner stand as a testament to engineering ingenuity, playing a pivotal role in maintaining optimal indoor climate control. These coils, meticulously crafted from aluminum, serve as the backbone of the cooling process, efficiently absorbing heat and humidity from the air, ensuring a comfortable and refreshing living environment.

Their unique properties, including exceptional thermal conductivity and corrosion resistance, make them ideally suited for this demanding application. As refrigerant circulates through the coils, heat is effectively transferred to the outdoor unit, resulting in a significant reduction in indoor temperature and humidity levels.

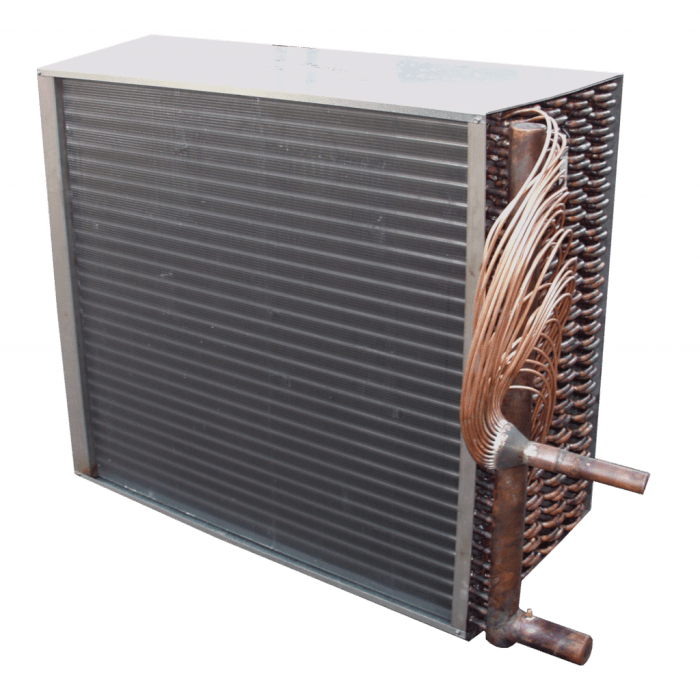

1. Metal Aluminum Coils in Air Conditioners

Metal aluminum coils are essential components in air conditioners, serving the crucial function of heat exchange. These coils are designed to absorb heat from the warm indoor air and release it outside, thereby cooling the indoor environment.

The use of metal aluminum coils in air conditioners offers several advantages. Aluminum is a highly efficient conductor of heat, allowing for effective heat transfer. Additionally, aluminum is lightweight, corrosion-resistant, and durable, ensuring longevity and reliability in demanding operating conditions.

2. Construction and Design of Metal Aluminum Coils

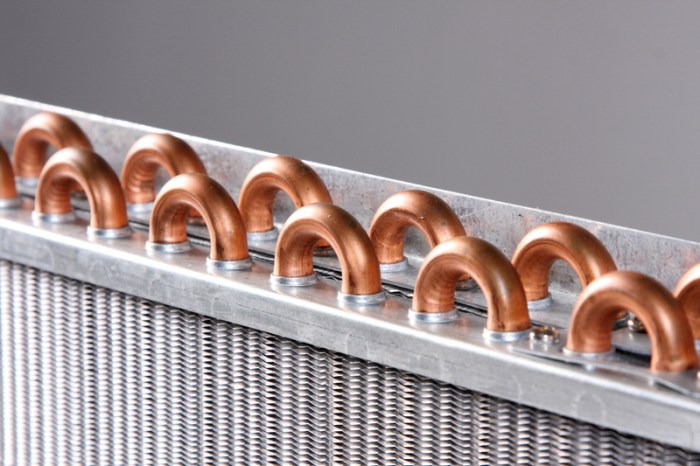

Metal aluminum coils are typically constructed from thin, corrugated aluminum sheets. The corrugated design increases the surface area of the coils, maximizing heat transfer. The coils are assembled into a serpentine pattern, allowing for optimal airflow and heat exchange.

There are two main types of metal aluminum coils used in air conditioners: flat coils and round coils. Flat coils are typically used in smaller units, while round coils are used in larger units. Round coils offer the advantage of higher heat transfer efficiency due to their increased surface area.

3. Manufacturing Process of Metal Aluminum Coils, The metal aluminum coils in an air conditioner

The manufacturing process of metal aluminum coils involves several steps:

- The aluminum sheets are cut to the desired size and shape.

- The sheets are corrugated to increase their surface area.

- The coils are assembled into the desired serpentine pattern.

- The coils are brazed or welded to ensure a leak-proof seal.

- The coils are tested for leaks and performance.

Quality control measures are implemented throughout the manufacturing process to ensure the coils meet the required standards.

4. Performance and Efficiency of Metal Aluminum Coils

Metal aluminum coils play a crucial role in determining the performance and efficiency of air conditioners. The heat transfer efficiency of the coils directly affects the cooling capacity of the unit. Aluminum coils offer high heat transfer efficiency, resulting in effective cooling performance.

The performance of metal aluminum coils is typically measured by their coefficient of performance (COP). COP is the ratio of the cooling capacity of the air conditioner to the power consumed. Higher COP values indicate better energy efficiency.

5. Maintenance and Troubleshooting of Metal Aluminum Coils

Regular maintenance of metal aluminum coils is essential to ensure optimal performance and longevity. Maintenance tasks include:

- Cleaning the coils to remove dust and debris.

- Inspecting the coils for leaks or damage.

- Tightening any loose connections.

Troubleshooting common issues with metal aluminum coils involves identifying the symptoms and implementing appropriate solutions:

- Reduced cooling capacity:Clean the coils or check for leaks.

- Leaks:Replace the damaged coil.

- Loose connections:Tighten the connections.

6. Environmental Impact of Metal Aluminum Coils

Metal aluminum coils have a relatively low environmental impact. Aluminum is a recyclable material, and the recycling process consumes significantly less energy than the production of new aluminum. Air conditioners with aluminum coils can be recycled at the end of their lifespan, reducing waste.

However, the manufacturing process of aluminum coils does release greenhouse gases. To mitigate this impact, manufacturers are implementing sustainable practices, such as using recycled aluminum and reducing energy consumption during production.

FAQ Overview: The Metal Aluminum Coils In An Air Conditioner

What is the purpose of metal aluminum coils in an air conditioner?

Metal aluminum coils serve as heat exchangers, absorbing heat and humidity from the indoor air and transferring it to the outdoor unit, resulting in a cooler and drier indoor environment.

Why are metal aluminum coils used in air conditioners?

Aluminum coils are preferred due to their excellent thermal conductivity, corrosion resistance, and lightweight properties, making them highly efficient and durable in this demanding application.

How do metal aluminum coils contribute to air conditioner efficiency?

The efficient heat transfer properties of aluminum coils allow for optimal cooling performance, reducing energy consumption and ensuring a more cost-effective operation.